The Indian manufacturing industry is a powerhouse, contributing significantly to the country's economic growth.Indian organizations are constantly striving to stay ahead of the curve and maintain a competitive edge. One methodology that has proven to be a game-changer in driving operational excellence and sustainable growth is Six Sigma. This data-driven, disciplined approach focuses on minimizing defects, reducing variability, and optimizing processes, enabling organizations to identify and eliminate root causes of problems, streamline operations, and consistently deliver high-quality products and services. At IMC Institute, we recognize the immense potential of Six Sigma in the Indian manufacturing sector and are proud to offer world-class certifications that empower professionals to unlock their true potential and propel their organizations to new heights. Our comprehensive training programs are tailored to the unique needs of the industry, equipping participants with the knowledge, skills, and tools necessary to drive transformative change and achieve operational excellence.

What is Six Sigma?

Six Sigma is a quality improvement methodology that utilizes a data-driven approach to eliminate defects and reduce variances in any process. It follows the DMAIC cycle: Define, Measure, Analyze, Improve, and Control. By implementing Six Sigma, manufacturing companies in India can achieve significant benefits, including:

Reduced Costs: Minimize waste, rework, and scrap by identifying and eliminating root causes of defects.

Improved Quality: Enhance product and service quality, leading to higher customer satisfaction.

Increased Efficiency: Streamline processes, optimize resource utilization, and boost productivity.

Enhanced Profitability: Achieve cost savings and improve product quality, leading to a significant increase in profitability.

The Six Sigma Advantage for Indian Manufacturers

The Indian manufacturing industry has embraced Six Sigma as a game-changer, recognizing its ability to drive tangible results and foster a culture of continuous improvement. By implementing Six Sigma principles, Indian manufacturers can enjoy numerous benefits, including:

Enhancing Product Quality: Six Sigma methodologies help organizations minimize defects and variability, resulting in consistent product quality that meets or exceeds customer expectations. This not only leads to increased customer satisfaction but also reduces costs associated with rework, returns, and potential recalls.

Optimizing Processes: Through systematic process analysis and improvement, Six Sigma enables manufacturers to identify and eliminate non-value-added activities, streamline operations, and boost productivity. This, in turn, translates into cost savings, increased efficiency, and a competitive advantage in the market.

Reducing Waste and Inefficiencies: Six Sigma's focus on lean principles and waste elimination empowers organizations to identify and eliminate sources of waste, whether in the form of excess inventory, unnecessary transportation, or inefficient processes. By minimizing waste, manufacturers can optimize resource utilization and improve profitability.

Fostering a Culture of Continuous Improvement: Six Sigma instills a mindset of continuous learning and improvement within organizations. By equipping employees with the necessary tools and techniques, Six Sigma encourages a proactive approach to identifying and addressing areas for optimization, fostering a culture of innovation and adaptability.

Enhancing Customer Satisfaction: Ultimately, Six Sigma's emphasis on quality, consistency, and process excellence leads to improved customer satisfaction. By delivering superior products and services that consistently meet or exceed customer expectations, manufacturers can strengthen their brand reputation and cultivate long-lasting customer loyalty.

Six Sigma Belts: Empowering Your Manufacturing Operations Team

At IMC Institute, we offer a comprehensive Six Sigma certification program designed specifically for professionals in the Indian manufacturing industry. We understand the importance of equipping your team with the right skills to drive continuous improvement. Our program offers certifications for two key

Six Sigma belts:

Six Sigma Green Belt Certification:

Ideal for mid-level professionals involved in process improvement projects. Gain a solid understanding of Six Sigma principles and methodologies. Learn to identify and analyze process problems using statistical tools. Develop skills to implement improvement initiatives within defined projects.

Certification:

On successful completion of the course and course requisites, the candidate will receive Internationally recognized Six Sigma Green Belt Certification.

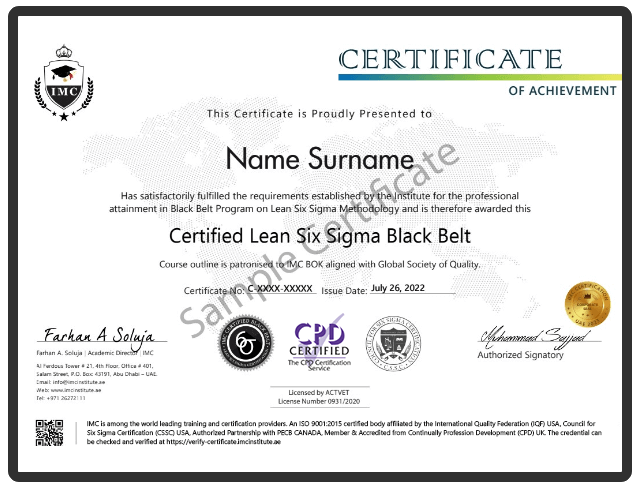

Six Sigma Black Belt Certification:

Designed for experienced professionals leading Six Sigma projects. Master advanced Six Sigma techniques and statistical analysis tools. Develop leadership skills to champion and mentor Six Sigma initiatives within the organization.

Drive large-scale process improvement projects, resulting in significant cost savings and efficiency gains.

Certification:

On successful completion of the course and course requisites, the candidate will receive Internationally recognized Lean Six Sigma Black Belt Certification.

Power of Six Sigma with IMC Institute's Exclusive Offer!

At IMC Institute, we are committed to empowering professionals in the Indian manufacturing industry. For a limited time, we are offering a special discount of 60% on our Six Sigma certification programs! This is an excellent opportunity to equip your operations team with the skills and knowledge to drive continuous improvement within your organization.

Don't miss out on this incredible opportunity! Contact IMC Institute today to learn more about our Six Sigma certification programs and take advantage of this exclusive offer. Together, let's elevate your manufacturing operations to new heights of efficiency and profitability!

Summary:

In this blog post, we delve into the essence of Six Sigma and its profound impact on the Indian manufacturing industry. We explore the numerous advantages of implementing Six Sigma principles, including enhanced product quality, optimized processes, reduced waste and inefficiencies, fostered continuous improvement, and increased customer satisfaction. Furthermore, we highlight the various Six Sigma certifications offered at IMC Institute, each designed to equip professionals with the expertise required to drive process improvement initiatives and achieve operational excellence. From the foundational Green Belt certification to the prestigious Black Belt credential, and even the comprehensive Lean Six Sigma programs, our training programs cover a wide range of skill levels and focus areas. Throughout the post, we emphasize the practical application of Six Sigma methodologies in the Indian manufacturing context, drawing upon real-world examples and success stories. We underscore the importance of leveraging robust statistical tools and techniques to identify and address root causes of problems, streamline operations, and consistently deliver superior products and services.